高性价比物流驱动系统诺德推出三种优化配置380v电机功率一览表展示其简明智慧

随着工厂驱动装置的日益增多,通过高效配置的设备型号可以节省高达70%的总拥有成本。因此,诺德驱动集团专门针对物料搬运和输送机应用推出三种优化配置的高效变频驱动系统。它们能满足邮政枢纽、内部物流应用及行李处理系统的典型需求。其标准化设计还大大简化了采购、工程设计、调试和备件库存等流程。此外,它们便于安装、操作和维护。

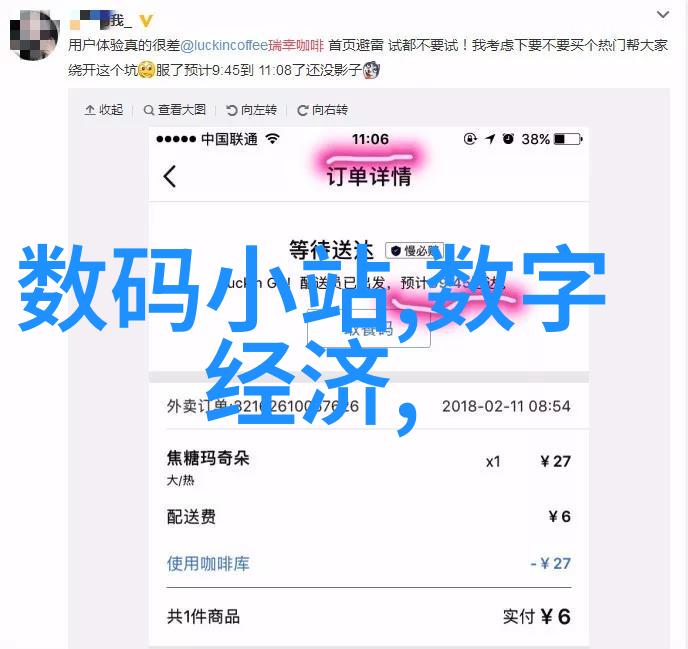

图1:在输送系统中,实现驱动标准化可节省高达70%的总拥有成本

与其他方法相比,优化驱动系统的型号除了能降低能耗,还大大节省了总体拥有成本(TCO)。因此,驱动系统制造商需针对特定的行业应用提供可行的标准化产品。优化产品型号可以简化采购流程,包括首次采购及后续的其他订单,同时使得库存管理更轻松。此外,它们还能简化驱动系统供应商、OEM以及终端用户的计划和工程设计流程。

当然,实现标准ization需要克服诸多挑战,例如尽量选择配置较少且能满足各种任务需求的驱动system,此外产品规格不宜过大。因此,driver system工程师需要深入分析具体行业의 driver方式及具体应用需求。

诺德drive group多年来一直致力于为内部material logistics及airport industry开发high efficiency drive technology,在丰富's industry experience基础上,不同industry为这些industry开发了含three kinds of optimization models'LogiDrive product series. They not only can greatly simplify the process of procurement, engineering design, system maintenance and employee training, but also significantly reduce the required inventory spare parts for postal hubs, warehouses and baggage handling systems, achieving a 70% reduction in total cost of ownership.

Very flexible three types LogiDrive series can provide drive solutions for conveyor systems hundreds meters long. Its variable speed drives use plug-in connectors; through shorter power cables to connect the drive systems. NORD has also customized products lines specifically for internal logistics and airport technologies; these three drive system models meet all typical performance requirements.

Moreover, power 1.1 kW, 1.5 kW or 2.2 kW IE4 super-efficient permanent magnet synchronous motors are combined with high-efficiency two-stage helical gear worm gear reducers to configure two specifications of driving systems with torque up to 260Nm.

NORDAC LINK series variable-speed drives have a larger speed range, higher overload capacity and multiple unique features. Their interfaces are compatible with all commercial communication protocols including PROFINET, Ethernet POWERLINK, EtherCAT and EtherNet/IP.

Figure 2: Distributed control systems can easily adjust settings and run switch

User-friendly type LogiDrive system uses removable coding connectors for quick safe installation; devices on-site maintenance switches key switches direction switches facilitate flexible setting or adjustment single axis operation; sensors data collected by frequency inverters sent directly to higher level systems avoid wiring.

Furthermore pre-set function-based frequency inverters simplify maintenance work replaceable components easy-to-use type compact drives lightweight alloy casing reduces weight by 25% compared to steel drives facilitates mobility IE4 super-efficient synchronous motor energy-saving maximum limit frequent light load conveyor applications shorten user investment payback period Figure3 & Figure4: LogiDrive equipped IE4 high-efficiency motor quickly achieves investment returns in frequent partial-load applications

Overall safety The LogiDrive system safely effectively drives horizontal inclined vertical conveyors Load monitoring automatically stops application failure protects driven equipment NORD provides TÜV-certified electronic modules each driven axis meets EN61800-5-2 standard STO SS1 safety functions Field-oriented vector control enables precise control For example crane applications they provide full torque zero speed simultaneously reliable transmission set speeds even under load fluctuations Figure5: NORD demonstrates main functions YouTube video simple flexible connection options